Multi-Contact Modules for Valve Terminals | Pneumatic Control

Multi-Contact Modules for Valve Terminals

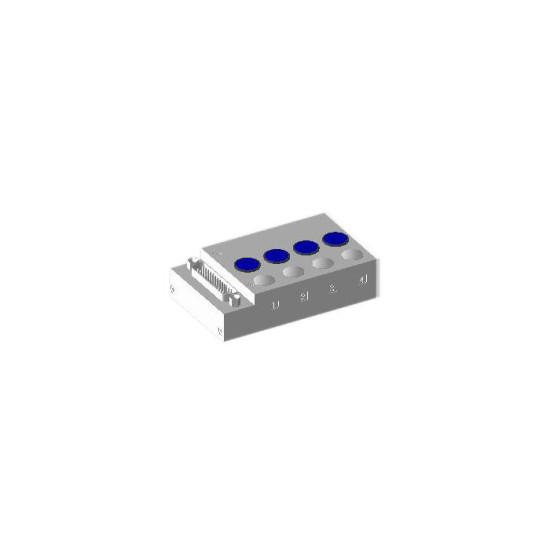

Multi-contact modules for valve terminals represent an advanced solution in industrial automation, allowing centralized connection of multiple solenoid valves through a single connector. These systems, also known as MCS (Multi Connector System), significantly optimize pneumatic installations by reducing individual wiring and simplifying both assembly and maintenance of valve assemblies.

These modules are specifically designed to integrate with modular kits and valve terminals, providing a compact and reliable electrical interface between the control system and pneumatic valves. The main feature of these devices is their ability to manage multiple electrical signals through a single 25-pin D-Sub connector, which drastically reduces installation time and the possibility of wiring errors.

Key Technical Specifications

Multi-contact modules are characterized by precise technical specifications that determine their compatibility and application:

- Compatibility with specific valve series (such as SF2000 1/8" or SF4000 1/4")

- Unimodular or bimodular configurations depending on installation requirements

- 25-pin D-Sub connectors that allow connection of up to 14 valves in some models

- Standard operating voltages of 24V DC or 12V DC

- Compact design that minimizes space required in the control cabinet

Key Points: Technical Specifications

- 25-pin D-Sub connectors for multiple valves

- Compatibility with specific series (SF2000, SF4000)

- Available in unimodular and bimodular versions

- Operation at 24V DC or 12V DC

Advantages in Industrial Applications

Implementing multi-contact modules in industrial pneumatic systems offers numerous benefits:

- Reduced installation time: Centralized wiring eliminates the need to individually connect each valve.

- Greater reliability: Fewer connections mean fewer potential points of failure.

- Ease of maintenance: Troubleshooting is simplified thanks to centralized connection.

- Cleaner design: Significant reduction of visible wiring in the installation.

- Less space required: The concentration of connections allows for more compact control cabinets.

Common Applications

Multi-contact modules for valve terminals find application in various industrial sectors where precise control of multiple pneumatic actuators is required:

- Automated assembly lines

- Packaging machinery

- Material handling equipment

- Sorting systems

- Food and pharmaceutical industry machinery

- Testing and quality control equipment

Selection Criteria

When choosing the appropriate multi-contact module for a specific application, it is essential to consider several factors:

- Valve compatibility: Verify that the module is compatible with the series and size of the valves to be used.

- Number of stations: Determine the number of valves that will be connected to the module (from 4 to 14 depending on the model).

- Module type: Choose between unimodular or bimodular configurations according to installation requirements.

- Supply voltage: Ensure that the module voltage (12V or 24V) is compatible with the control system.

- Connector type: Although the 25-pin D-Sub is standard, verify compatibility with existing cables and controllers.

Highlights: Selection

- Verify compatibility with specific valve series

- Determine the necessary number of stations

- Consider the system's voltage requirements

- Evaluate available space for installation

In the USA market, leading pneumatic suppliers offer a wide range of multi-contact modules for valve terminals from recognized manufacturers such as SMC, Festo, and Parker, ensuring high-quality solutions for your pneumatic systems. Pneumatic specialists can advise you on selecting the most suitable module for your specific needs, ensuring perfect integration with your valve plates and existing control systems.

Frequently Asked Questions

What is the advantage of using multi-contact modules over individual valve wiring?

Multi-contact modules significantly reduce installation time and complexity by allowing multiple solenoid valves to be connected through a single connector. This centralized approach minimizes wiring errors, improves system reliability, simplifies troubleshooting, and creates a cleaner, more compact control cabinet design. In high-density automation applications common in U.S. manufacturing, this translates to reduced downtime and maintenance costs.

Are multi-contact modules compatible with all valve terminal systems?

No, multi-contact modules are designed to be compatible with specific valve series and manufacturers. When selecting a module, it's essential to verify compatibility with your particular valve terminal system. Most major U.S. pneumatic suppliers like Parker, Festo, and SMC offer multi-contact modules specifically designed for their valve terminal systems, ensuring proper electrical and mechanical integration.

How many valves can typically be controlled with one multi-contact module?

The number of valves that can be controlled with a single multi-contact module varies by model and manufacturer. Standard modules with 25-pin D-Sub connectors typically support between 4 and 14 solenoid valves, depending on whether the valves are single or double solenoid. For larger automation systems requiring more valves, multiple modules can be used or alternative communication protocols like fieldbus systems might be more appropriate.

Login and Registration Form