Pneumatics valves

The valves and solenoid valves section includes elements for controlling the flow of compressed air and other media. They are used in the simplest and the more demanding systems that control actuators.

The most popular pneumatic valves, pneumatic solenoid valves , check valves and quick release valves are available in various versions. Standard, i.e. brass and stainless steel for an aggressive environment. A wide selection of connections and the flow rate is important in choosing the right valve. Ball valves are also suitable for installation under pneumatic and electric drives.

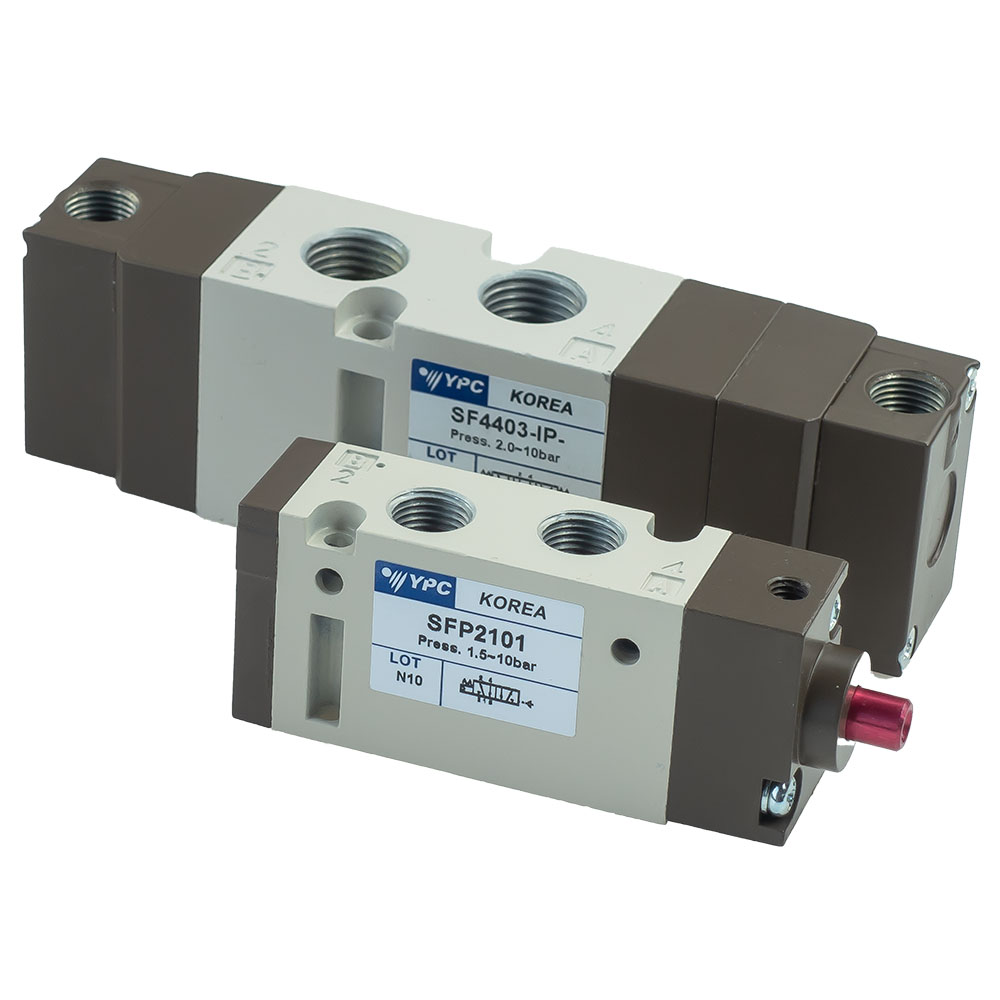

We are a direct distributor in the country of the flagship Korean manufacturer of Yonwoo Pneumatic valves. More than a dozen different series of valves with various dimensions and parameters made in accordance with the standards: pneumatic valves NAMUR, ISO-0, ISO-1, ISO-2, our consultant provides our consultant with the selection of an appropriate replacement for other manufacturers.

Thanks to our over 20 years of experience, we have built a large warehouse of valves and solenoid valves, thanks to which we are able to select the appropriate control for the user "on the spot".

Our valves and solenoid valves have 3d models for each product offered, this will enable the valve to be incorporated into the design, and the appropriate certificate to be obtained. They are available for download in the "Download" tab on the product page.

We offer compressed air operated valves with connection diameters from M5 to 1 ”and NO, NC functions. At the customer's request, we can offer Ex valves.

Pneumatics valves with different functions

The pneumatic solenoid valves that we offer allow you to buy a separate coil and plug of any voltage, in a classic version or with a voltage signaling diode.

The shut-off, i.e. 2/2 in NO and NC versions, which are used for liquids and inert gases, are standard with NBR seals.

The SF, SCE series of solenoid valves used for actuator control systems are highly appreciated on the domestic market. For each diameter from M5 to 1 ”there is each function: 3/2, 5/2, 5/3, mono and bistable. The possibility of mounting on the valve plate allows the construction of entire valve terminals. Each of the solenoid valves has a manual override, it is a button (IP marking) or a switch (IL)

Valves and solenoid valves - types

Mechanical valves: HLV, KMV, FT are of high quality. Among them, foot, manual and lever valves have strong aluminum housings, replacing the plastic ones offered by other manufacturers. They are also available in versions from 1/8 ”to 1/2”. The PMV series allows for easy panel mounting.

Valve terminals are built on SCE solenoid valves through a connection plate and MCS module, and enables control via the LPT port. The advantage is the possibility of installing solenoid valves with different functions.

Throttle valves are responsible for increasing or reducing the air flow, which in turn gives many possibilities for their application. The most popular use of this type of valve is to connect it to the system between the pneumatic actuator and the control valve. By means of the knob, the user adjusts the position of the needle so that the actuator works slower or faster.

Spool valves are used to quickly close or open a system. When the valve is closed, the air behind it is released into the atmosphere. Compact and solid construction does not make it difficult to use them, for example, with pneumatic tools. They come with threads from 1/8 "to 1"

Slanted pneumatic valves are used in systems where the speed of operation is very important, resistant to high temperature, they are used for hot steam. The stainless steel housing and PTFE sealing make it suitable for installation in an aggressive environment. Air-operated valves come in a variety of configurations. Monostable and bistable pneumatic valves with a cross-section from 1/4 ”to 2” available from stock.

The valve group also includes elements required by the supervision for pressure vessels. The safety valves in question are used to protect the expansion tank against pressure overload. It is important to select the valve opening pressure and its capacity. It is worth paying attention to the fact that the pneumatic solenoid valve is marked and has full technical documentation.

Login and Registration Form