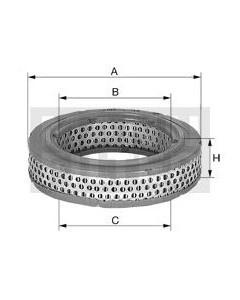

Air filter for the compressor

Choosing a compressor that generates compressed air for pneumatic systems should go hand in hand with the selection of an appropriate filter. During operation, the compressor collects impurities that can pose a real threat to the system components. Therefore, an air filter for the compressor is essential. Its task is to treat compressed air and purify it of the elements of the pneumatic system. A well-selected compressor filter has a huge impact on the reliable and efficient operation of the entire system.

What exactly is a compressor?

In modern industry, pneumatic systems turn out to be irreplaceable, in which individual elements are supplied by compressed air. They are found both on production lines, transport lines, as well as in small workshops. A compressor, also known as a compressor, is responsible for generating air under high pressure up to 10 bar. Then, compressed air is introduced into the system and supplies the individual components. There are numerous elements responsible for directing the airflow that are responsible for the flow.

However, some debris may collect in the compressor and this is completely normal. It is about dust and other particles that penetrate inside the compressor. They pose serious threats to the compressor itself as well as to the pneumatic systems. Flawlessly clean air is essential for proper operation. This is where the compressor air filter comes in. With its help, you can effectively stop even the smallest contaminants, thanks to which the system components will be supplied with perfectly clean compressed air.

Compressors can be divided into displacement and flow compressors. The design of the compressor is very important in the context of choosing the correct filter. In the category of displacement compressors, we can mention: screw , piston, diaphragm, vane and scroll compressors. In turn, the group of flow compressors includes radial, diagonal, axial and vortex compressors. Pneumatig offers filters for various types of compressors .

What is the role of the compressor air filter?

For the correct operation of pneumatic systems, spotlessly clean air is required. Any soiling can lead to numerous faults over time, as well as a decrease in performance. A professional compressor filter is used to keep these contaminants in the filter. Thanks to this, they do not pose a threat to the compressor and the pneumatic system. From time to time , the air filter for the compressor should be replaced with a new one. We can distinguish filters combined with a compressor, in which only the cartridges responsible for air filtration and treatment are replaced.

Filtration is a process in which solid contaminants and oil necessary for the proper operation of the compressor can be effectively retained. The air compressor filter is designed in such a way as to guarantee perfect filtration over a longer period of time. A well-selected filter is able to ensure optimal filtration even for 2-3 thousand hours of system operation. Of course, a lot depends on the specificity of the system and the pressure of the compressed air. In some industries, such as the medical and food industries, the requirements for air filtration are much greater.

Why is a compressor filter so important?

Solid contamination and oil falling into the pneumatic system pose a great threat to the sensitive elements controlling the air flow, as well as the working elements responsible for performing specific tasks. Therefore, the compressor air filter is an essential element of the entire system, ensuring reliable and effective operation. Without a filter, serious faults could possibly occur within a few months, resulting in downtime and additional operating costs.

Not only the pneumatic system is at risk, but also the compressor itself. The lack of a filter would lead to the necessity of earlier replacement of oil, bearings and other consumable parts. There is also a risk of damaging the screw stage of the compressor, which may mean that the only salvation will be a very costly regeneration or replacement of this part. This shows how the compressor air filter plays a responsible role in pneumatic systems. Therefore, it is so important to choose an appropriate and compatible filter.

How does an air compressor filter work?

The filter has a special insert containing a pleated fabric with a very high density of weaves. It is she who will be responsible for retaining solid impurities and oil. The air filter for the compressor can also cooperate with other air treatment systems, e.g. an oil mist generator, which is introduced with the air to lubricate the moving elements of the pneumatic system. The key criterion is the scope and precision of filtration, which determine the minimum contaminants retained by the filter, as well as how much air is able to clean the filter during operation. The pressure of the compressed air itself can also play a role in this matter.

What are the benefits of a good compressor air filter?

Professional filters for compressors guarantee proper protection of the compressor itself, as well as all elements of the pneumatic system supplied with compressed air. The filter traps contaminants that could lead to serious malfunctions as well as reduce the efficiency and performance of the entire system. Therefore, we can safely say that the compressor air filter allows you to reduce the risk of faults leading to downtime and additional operating costs.

The filter also saves money, as it prevents oil from escaping from the compressor, so it does not need to be changed ahead of time. The system powered by perfectly clean and properly treated air works much more efficiently, especially in the wider perspective of time. All this makes the compressor air filter an indispensable element of every compressor, and its timely replacement is of great importance in the context of the efficiency of the entire system.

What should good compressor filters look like?

The design and materials used for the production of filters have a large impact on the application as well as the specificity of the filter's operation. The key issue is the range of performance and precision. The first factor determines how much air under a certain pressure will be able to treat the filter in continuous operation. The precision indicator, on the other hand, tells you how small particles and debris the filter is able to capture. In some industries, the requirements are stricter, which of course means a need for a more expensive and better filter.

In other words, a good compressor air filter is able to efficiently treat large amounts of air under high pressure, and at the same time ensures very accurate retention of particles that with the air will not get into the elements of the pneumatic system. A properly selected filter must also match the type and thread diameter, which determines the compatibility of the filters with specific compressor models.

How often should compressor filters be replaced?

In order to maintain the efficient operation of the compressor over a longer period of time, periodic wear replacements are necessary. Oil, bearings and compressors filters are also replaced. However, the question is how often such replacement should be carried out in order to keep the compressed air perfectly clean. It is recommended that the compressor's air filter be replaced at least every 2.5-3 thousand hours of operation, but not less frequently than once a year. Of course, in some industries, such as medical and food, applicable standards may require more frequent replacements.

What should I pay attention to when buying an air compressor filter?

Much depends on what type of compressor we are dealing with. Please note that there are compressors with replaceable filters as well as compressors with combination filter, where only the filter itself needs to be replaced. Nevertheless, reciprocating and screw compressors are based on very similar filters, although their structure may differ slightly. When selecting a filter, take into account the size of the connection, which consists of the type and diameter of the thread. An important issue is also the type of trigger: automatic or manual.

The selection criteria should take into account the scope and precision of filtration, bearing in mind that in some industries stringent standards must be met. The above differences make the air filter for the compressor available at various prices, from several dozen to several hundred zlotys. It is also worth checking the manufacturer's reputation and reading more information about the filter you choose. It should be remembered that the compressor air filter ensures reliable and effective operation, protecting both the compressor and the elements of the pneumatic system against faults caused by insufficient quality of compressed air.

Compressor air filters offered by Pneumatig

Pneumatig's offer includes only proven and high-quality compressor filters made by trusted and reputable manufacturers. We have filters of various types and thread diameters, thanks to which you can easily select parts tailored to your individual needs. We also have the necessary spare parts and cartridges for compressors equipped with combined filters. Our offer includes only products of the highest quality and made in compliance with all standards. Choosing an air filter for a compressor in the Pneumatig store, you gain a guarantee of effective and reliable operation of pneumatic systems, which will be supplied by impeccably clean air.

Login and Registration Form