ISO P Series Pneumatic Valves | Industrial Standard Control

ISO P Series Pneumatic Valves: Industrial Standard Directional Control

ISO P Series pneumatic valves represent our line of pneumatic directional control valves designed according to ISO 5599 standard, an international specification that ensures universal compatibility and interchangeability between different manufacturers. This feature makes them ideal components for industrial pneumatic systems where standardization and reliability are fundamental requirements.

Precisely constructed to strictly comply with ISO 5599 specifications, these valves offer a robust and versatile solution for controlling pneumatic actuators in demanding industrial environments. Their pneumatic actuation provides safe operation in areas where electrical signals could pose a risk, such as explosive or highly corrosive environments commonly found in American chemical processing plants and oil refineries.

The ISO P Series is available in different standardized sizes (ISO 1, ISO 2, ISO 3), each optimized for various flow rates and pressure requirements. This standardization facilitates both initial selection and eventual replacement or system expansion, providing long-term flexibility that aligns with ANSI/NFPA standards commonly used throughout US manufacturing facilities.

Key Features of ISO P Valves:

- Strict compliance with ISO 5599 standard for maximum compatibility

- Robust construction with high-quality materials for industrial environments

- Excellent flow capacity and quick response time

- Can be mounted on ISO valve blocks for complex systems

- Compatible with standardized pneumatic actuators such as ISO 15552 cylinders

- Multiple pneumatic actuation options

Typical applications for these valves include heavy industrial machinery, complex automation systems, production lines, packaging equipment, and any application requiring compliance with international standards and high reliability in pneumatic control. In the US market, these valves are particularly popular in automotive manufacturing plants throughout Michigan and Tennessee, food processing facilities in California and the Midwest, and aerospace manufacturing operations in Washington and Texas.

When selecting ISO P Series valves, it's important to consider factors such as the appropriate ISO size based on required flow rate, specific connections needed, and compatibility with existing control systems to ensure optimal integration in your application. Many US industrial facilities prefer these standardized valves as they simplify maintenance inventory and ensure compliance with global manufacturing standards.

Technical Specifications and Selection Guide

The ISO P Series pneumatic valves are available in three main sizes according to the ISO 5599 standard:

- ISO 1: Suitable for smaller applications with flow rates up to 750 l/min and operating pressures of 2-10 bar

- ISO 2: Medium capacity with flow rates up to 1,900 l/min and operating pressures of 2-10 bar

- ISO 3: High capacity with flow rates up to 3,800 l/min and operating pressures of 2-10 bar

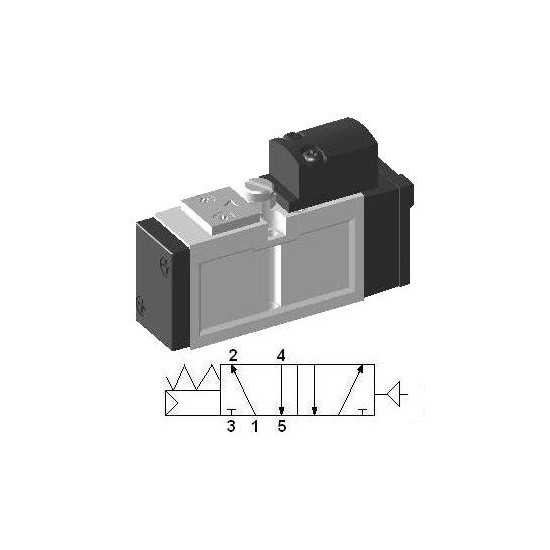

These valves are typically configured in 5/2 or 5/3 function designs, making them versatile for both single and double-acting cylinder control applications. The 5/3 configurations come with different center position options (closed center, open center, or pressure center) to accommodate various system requirements and fail-safe conditions.

Installation and Maintenance Considerations

For optimal performance in US industrial environments, ISO P Series valves should be installed in clean, dry locations with filtered compressed air systems. Regular maintenance should include:

- Periodic inspection of pneumatic connections for leaks

- Verification of proper pilot pressure (typically 3-8 bar)

- Checking for smooth operation of the valve mechanism

- Ensuring clean air supply through proper filtration systems

Most US facilities follow OSHA guidelines for pneumatic system maintenance, which recommend scheduled inspections and documentation of all pneumatic control components including these ISO P valves.

Advantages in American Industrial Applications

The standardized design of ISO P Series valves offers several specific advantages for US industrial users:

- Reduced Downtime: The interchangeability between manufacturers means replacement parts can be sourced quickly, minimizing production interruptions

- Simplified Inventory: Standardization allows maintenance departments to stock fewer spare parts while maintaining coverage for multiple systems

- Future-Proofing: As systems expand or change, the ISO standard ensures new components will integrate seamlessly with existing infrastructure

- Global Compliance: For US manufacturers exporting machinery, using ISO standard components ensures their equipment meets international requirements

What are the main differences between ISO P Series sizes?

The main differences between ISO P Series sizes (ISO 1, ISO 2, and ISO 3) are flow capacity, physical dimensions, and port sizes. ISO 1 valves typically handle flow rates up to 750 l/min with 1/8" to 1/4" ports, ISO 2 valves manage up to 1,900 l/min with 3/8" ports, and ISO 3 valves accommodate up to 3,800 l/min with 1/2" to 3/4" ports. The appropriate size should be selected based on your application's specific flow requirements and the actuator size being controlled.

Are ISO P Series valves compatible with US pneumatic systems?

Yes, ISO P Series valves are fully compatible with US pneumatic systems. While the US market has traditionally used both NFPA and ISO standards, the ISO 5599 standard has been widely adopted across American industry. These valves work with standard NPT or NPTF port threads common in US installations, and can be integrated with existing American-made pneumatic components. Many US manufacturers and distributors stock these valves specifically for the American market.

What maintenance schedule is recommended for ISO P valves in continuous operation?

For ISO P valves in continuous operation within US industrial environments, a quarterly inspection schedule is typically recommended. This should include checking for air leaks, verifying proper actuation, and ensuring clean air supply through appropriate filtration. In harsh environments like those found in chemical processing or food manufacturing, monthly inspections may be necessary. Most manufacturers recommend complete valve replacement or rebuilding after approximately 5-10 million cycles, depending on operating conditions and air quality.

Login and Registration Form