ISO Series Solenoid Valves: Standardized Pneumatic Solutions

ISO Series Solenoid Valves - Pneumatic Standardization and Compliance

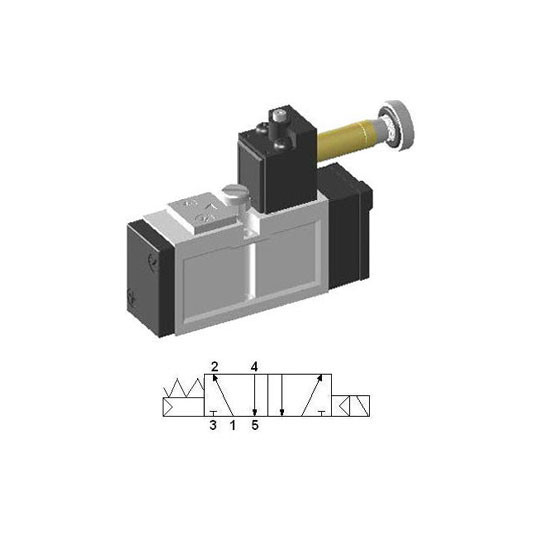

ISO Series solenoid valves represent our line of pneumatic valves designed in strict compliance with the ISO 5599 standard, ensuring complete compatibility and interchangeability in industrial pneumatic systems. This standardization offers significant advantages for engineers and technicians seeking reliable and universally compatible solutions.

Technical Specifications

- Standard: Compliant with ISO 5599

- Available sizes: ISO 1, ISO 2, ISO 3

- Body material: High-quality anodized aluminum

- Resistance: Excellent corrosion protection

- Mounting options: Individual or manifold

- Compatible coil voltages: 12V DC, 24V DC, 24V AC, 110V AC, 230V AC

- Compatibility: With SIV ISO valve blocks

Key Advantages

Manufactured by Yonwoo Pneumatic.co., Ltd. (YPC), these solenoid valves rigorously follow the dimensional and functional specifications established by the ISO 5599 standard, ensuring they can replace or complement components from other manufacturers that meet the same standard without requiring modifications or adapters. Precision internal components ensure reliable switching and consistent response times, which are essential for applications requiring precise synchronization.

Typical Applications

- Standardized industrial systems

- Applications requiring component interchangeability

- Installations requiring compliance with international standards

- Complex pneumatic systems with multiple control points

- Applications demanding precise synchronization and consistent response times

- Demanding industrial environments where robustness is essential

A key advantage of ISO Series solenoid valves is their versatility in terms of mounting options. They can be installed individually or in manifolds and are compatible with various types of coils and supply voltages, adapting to the specific requirements of each control system.

For applications requiring compliance with international standards, ISO Series solenoid valves offer the peace of mind of knowing that each component has been designed and manufactured following rigorous specifications, ensuring consistent performance and the ability to obtain compatible replacement parts globally.

Key Takeaways

- ISO 5599 compliance ensures universal compatibility across pneumatic systems

- Available in three standardized sizes (ISO 1, 2, and 3) for different flow requirements

- High-quality construction provides excellent durability in industrial environments

- Multiple mounting configurations and voltage options for maximum versatility

Implementation in US Manufacturing

In the American manufacturing sector, particularly in automotive production facilities across Michigan and the Southeast, ISO Series solenoid valves have become the standard choice for assembly line pneumatic systems. Their compliance with international standards makes them particularly valuable in facilities that operate under global manufacturing protocols or that need to maintain consistency with overseas operations.

The ability to directly interchange these valves with components from various suppliers provides US manufacturers with supply chain flexibility, reducing downtime and maintenance costs. This interchangeability is especially important given current global supply chain challenges, allowing maintenance teams to source compatible components from multiple vendors when needed.

Compliance with US Industrial Standards

Beyond ISO compliance, these solenoid valves also meet relevant ANSI/NFPA standards for pneumatic systems in industrial applications. This dual compliance is particularly important for US facilities that must adhere to both international and domestic regulatory frameworks, such as those in the food processing, pharmaceutical, and critical manufacturing sectors.

The robust construction and reliable performance of these valves make them suitable for use in applications where adherence to FDA, OSHA, or other US regulatory requirements is essential. Their anodized aluminum construction provides the corrosion resistance needed in challenging industrial environments while maintaining the lightweight properties that make installation and maintenance more manageable.

Frequently Asked Questions

What makes ISO Series solenoid valves different from non-standardized valves?

ISO Series solenoid valves are manufactured according to the strict dimensional and performance specifications of the ISO 5599 standard. This ensures complete interchangeability between different manufacturers' products, simplified maintenance, and global spare parts availability. Non-standardized valves may offer custom features but lack this universal compatibility, potentially leading to higher long-term costs and maintenance challenges.

How do I select the right ISO valve size for my application?

The selection primarily depends on your required flow rate. ISO 1 valves are suitable for smaller applications with flow rates typically up to 1000 Nl/min. ISO 2 valves handle medium flow requirements (up to 2000 Nl/min), while ISO 3 valves are designed for high-flow applications (up to 4000 Nl/min). Consider your actuator size, cycle time requirements, and system pressure when making your selection.

Are ISO Series solenoid valves suitable for outdoor or harsh environment applications in the US?

Yes, with proper considerations. The standard anodized aluminum construction provides good corrosion resistance for many industrial environments. For particularly harsh US environments like coastal areas with salt spray, chemical processing facilities, or extreme temperature locations (such as northern states or southern heat), consider options with enhanced environmental protection or enclosures. Special versions with NEMA 4X compatibility are available for extreme conditions.

Login and Registration Form