Air Filters for Screw Compressors: Efficiency and Protection

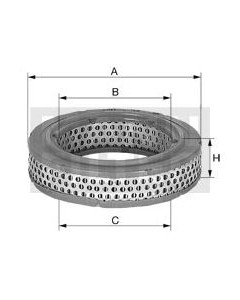

Air filters for screw compressors are critical components in industrial compressed air systems, specifically designed to protect compression elements and ensure the quality of produced air. In industrial environments where operational reliability is essential, these filters represent the first line of defense against contaminants that could compromise the performance and service life of screw compressors.

Unlike conventional filters, those designed for screw compressors are optimized to handle high volumes of air with minimal pressure drop, a fundamental characteristic for maintaining the energy efficiency of the compression system.

Technical Characteristics and Functionality

Screw compressor filters are characterized by their robust construction and high-quality materials that allow for:

- Efficient particle retention from 1 to 25 microns, depending on the filtration grade

- Aerodynamic design that minimizes air flow resistance

- Capacity to withstand continuous operation conditions

- Reinforced structure to resist vibrations and pressure differences

- Materials resistant to moisture and chemical contaminants present in industrial environments

The efficiency of these filters is primarily measured by their ability to remove particles without generating excessive pressure drops, a critical factor for the compressor's energy consumption. For every 0.1 bar of pressure drop, energy consumption can increase by approximately 1%, demonstrating the importance of selecting quality filters and maintaining them properly.

Key Takeaways: Essential Characteristics

- High particle retention capacity with minimal pressure drop.

- Specific design for the demands of screw compressors.

- Direct impact on the system's energy efficiency.

Types of Filters for Screw Compressors

Various types of air filters for screw compressors are available in the market, each adapted to specific needs:

- Primary intake filters: Constitute the first stage of filtration, eliminating large particles before air enters the compression system.

- Panel filters: Designed for installations with limited space, offering a compact solution without compromising efficiency.

- High-efficiency filters: Incorporate advanced filter media for applications requiring higher air purity.

- Service filter kits: Include all filter elements necessary for complete compressor maintenance.

For specific brands of compressors such as Atlas Copco GA or Atlas Copco G, there are filters designed according to the exact manufacturer specifications, ensuring a perfect fit and optimal performance.

Benefits of Proper Maintenance

Regular replacement of air filters for screw compressors provides multiple advantages:

- Reduction of energy consumption by up to 5-8%

- Extended service life of compression elements

- Decreased corrective maintenance costs

- Improved quality of produced compressed air

- Prevention of costly breakdowns in the air compressor

Industry studies indicate that approximately 70% of premature failures in screw compressors are related to inadequate filtration, which underscores the importance of not skimping on this seemingly simple but fundamental component.

Selection Criteria

When choosing air filters for screw compressors, it is essential to consider:

- Compatibility: Verify exact compatibility with the specific compressor model

- Flow capacity: Must meet or exceed the compressor's requirements

- Filtration grade: Select according to the air quality required for the final application

- Environmental conditions: Consider factors such as dust, humidity, or chemical contaminants present

- Maintenance interval: Evaluate the recommended replacement frequency and its operational impact

For particularly demanding environments, such as the food or pharmaceutical industry, filters with additional characteristics that meet specific industry regulations may be necessary.

Key Takeaways: Filter Selection

- Exact compatibility with the compressor model is critical.

- Filtration grade must align with air quality requirements.

- Environmental conditions determine the most suitable filter type.

Installation and Maintenance

To obtain maximum performance from air filters for screw compressors, it is fundamental to:

- Strictly follow manufacturer instructions during installation

- Respect recommended replacement intervals, generally between 2,000 and 4,000 operating hours

- Regularly inspect the filter condition, especially in environments with high particle concentration

- Ensure perfect sealing to avoid bypass of unfiltered air

- Consider installing differential pressure indicators to monitor clogging status

Proper preventive maintenance not only optimizes compressor performance but also significantly contributes to reducing long-term operating costs.

Login and Registration Form