Pneumatic connections

In order to be able to work with compressed air, it is not enough to have a compressor only. In addition to the source, we need hoses and pneumatic connectors with them. They can be divided into groups such as auto couplings, claw couplings, clamps for CU cables, and still popular "Christmas trees", plastic pneumatic couplings, ball valves, pneumatic quick couplings TYPE 21,26,27 and all kinds of strips, bands and finally threaded couplings and reductions.

The AUTO type plug-in nipple, or QUICK type, if you prefer, are used for direct connection of calibrated hoses, mainly: PA, PU, PE, PTFE and are the most frequently used connectors in pneumatics in the world.

Pneumatic connectors can be divided into:

- standard

- stainless

- mini

- The body is made of high-quality polyamide (PA 66) and nickel-plated brass.

- Sealing: NBR.

- Working temperature from -20 ° C to 80 ° C.

- Working pressure from 0 to 12 bar.

A separate group of pneumatic connectors are twisted connectors, where there is no seal and the conduit is sealed with a nut by pressing. This type of connector is mainly used where there may be higher temperature (above + 70 ° C), or strong stresses or twisting of the wires.

- Working temperature from -20 ° C to 70 ° C.

- Working pressure from -0.95 to 15 bar.

In addition, pneumatic couplings are divided into simple, all kinds of manifolds, tees "T" or "Y" type, pneumatic swivel bearing, slow and high-speed, elbows, straight-through pneumatic hose couplings, reduction plug couplings, cross-pieces or plugs and plugs, and ending with shut-off valves, regulators or valves with the possibility of venting.

Pneumatic plug connectors of this type are available both with male and female threads. Their assembly, connection with cables is not a hassle and allows for multiple safe disconnection.

Appropriate connectors can be selected for each industry branch, which in turn will protect us from leaks or breakdowns.

Pneumatic couplings - brass couplings

- Pneumatic quick couplings TYPE 21 DN 5

They are characterized by smaller dimensions and are used mainly where we are limited by the space and size of a tool. Successfully used in dentistry (dental units and prosthetics) and modeling (airbrushes).

The connection system has been the most popular for many decades around the world, which allows for free selection of all pneumatic connectors.

- Flow: 560 l / min.

- Working pressure: 0 to 35 bar.

- Working temperature: -20 ° C to 100 ° C (N

- Pneumatic quick couplings TYPE 26 DN 7.2

The most popular pneumatic fitting used in almost every field of industry. A wide range of possibilities allows you to connect almost any device, including cables and tools.

Although they can differ in appearance, their common feature on the European market makes them compatible.

Flow: 1000 l / min.

- Working pressure: 0 to 35 bar.

- Working temperature: -20 ° C to 100 ° C (NBR seal).

Pneumatic connectors - information

- Fasteners

Due to the use of a medium such as compressed air and the presence of moisture in it, corrosive elements, mainly steel, are not used. For this reason, the most commonly used material is pure brass and

electroplated. In industries where conditions are either aggressive or sanitary requirements, stainless steel material is used.

We are able to propose any nipples, reductions, couplings, sockets that only the client chooses for himself, for assembly or expansion, e.g. for compressed air installations.

Characteristics of fasteners:

- Material: brass, nickel-plated brass, stainless steel.

- Working temperature: ~ -20 ° C to ~ 150 ° C.

- Maximum working pressure: 16 bar.

Pneumatic couplings - claw

It is a reliable and very solid connection. It is successfully used both with the medium such as compressed air in pneumatics, water in horticulture, or oils and others used in construction.

It is recommended to use claw couplings where the flow should be high, which is ensured by the "mushroom-free" design of the claw coupler.

Quick connection claw pneumatic couplings value them with an exceptionally reliable and damage-resistant connection.

Before choosing, we should remember about the type of connector because there are various options on the market - center distance. 40 mm spacing - typical connectors for water, air, etc. GEKA Plus-such we propose a 41 mm spacing - American, 42 mm spacing - typical European.

And the type of medium for the correct selection of the seal, NBR (including the option for drinking water) or Viton. The second seal is used for executions e.g. made of stainless steel or higher temperature.

Characteristics for GEKA Plus claw couplings

- Easy connection and disconnection protection against accidental disconnection of high flow.

- Working pressure max. 42 bar.

- Temperature: max 105 ° C

Ball valves

Ball valves have a very wide range of applications. From the most commonly used in installations supplying cold and hot water, we know these from our own experience, to the machine, food and chemical industries.

They are used as an element of the installation to supplement or shut off the medium such as compressed air, thanks to their design they ensure long operation and tightness.

The simplicity of use and the types of execution allow the use of ball valves almost everywhere, making them universal.

Ball valves can be available in the following options: WZ (external thread, commonly known as nipple thread), WW (internal thread on both sides)

Another group of valves includes three-way valves with the option of indicating the flow path for the media: "T" or "L" and with a "lock", the so-called lever lock.

Pneumatic connectors - characteristics

Compressed air, gas, water, steam, oil and all similar consistency products.

- Working temperature: -20 ° C + 130 ° C.

- Max. working pressure: 16-25 bar depending on the model.

- Body: nickel-plated brass or pen casting

- Lame inside: nickel-plated or chrome-plated brass

- Handle: steel (lock version), plastic cover, plastic

- Spindle: nickel-plated brass.

- Ball seal: PTFE.

- Spindle seal: PTFE.

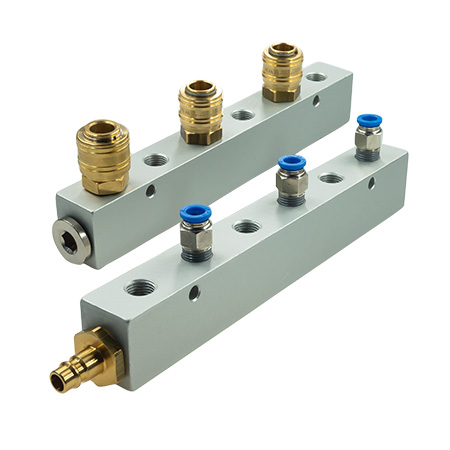

Pneumatic connectors - Manifolds, manifolds, distributors

Mains made of anodized aluminum are used to distribute, among others compressed air, eliminating the number of connectors or hoses in place.

For requirements other than the machine industry, where the conditions are particularly demanding, it is proposed to make stainless steel, or with the use of plastic with a threaded insert element.

Very popular due to the possibility of mounting to fixed elements in all kinds of installation works or control modules in industry, and the possibility of expanding with other plug-in pneumatic connectors.

"Worm" clamps

Solid, strong, galvanized wide ties from the British manufacturer Jubilee. Used wherever a strong clamp and tightness on pipes is required in the automotive, agricultural industry in ventilation or vacuum.

Multiple use and a wide range of dimensions make them cheap in the group of clamps. Perfect for pneumatic connections with the so-called "Christmas tree". They are available galvanized and stainless.

- Thread seals

Sealing pneumatic threads, such as hydraulic or gas threads, has a significant impact on their subsequent tightness. Incorrectly performed will result in the necessity to repeat the entire sealing operation.

We can choose from Teflon tapes, glues or threads.

It all depends on the preferences or skills of the installer. For a specialist, any method will be good, but if we are inexperienced, glue will be a good choice. Here, the connection can be "loose" for several minutes to achieve tightness in a moment.

- Noise silencers

Pneumatics, where the driving force is compressed air, is characterized by a lot of noise during expansion-discharge into the atmosphere. Silencers are an ideal solution for companies where pneumatics is the basis for driving machines and devices. Silencers are essential wherever silence or noise reduction is required.

By using them, we not only care about the comfort of work, but we mainly protect our machines, tools, etc. against contamination from the outside. We must remember that all control devices that work with compressed air are sensitive to dirt. The continuous discharge itself will not cause "purging" and will not automatically clean the system, and machine standstill, leakage of the medium and production break are losses that many entrepreneurs cannot afford.

We divide silencers into the most commonly used threaded ones with the so-called bronze sinter, with or without regulation, flat, conical and made of plastic with the possibility of self-cleaning (granules). Made of stainless steel incl.

- plug-in

- to a vacuum

- suction