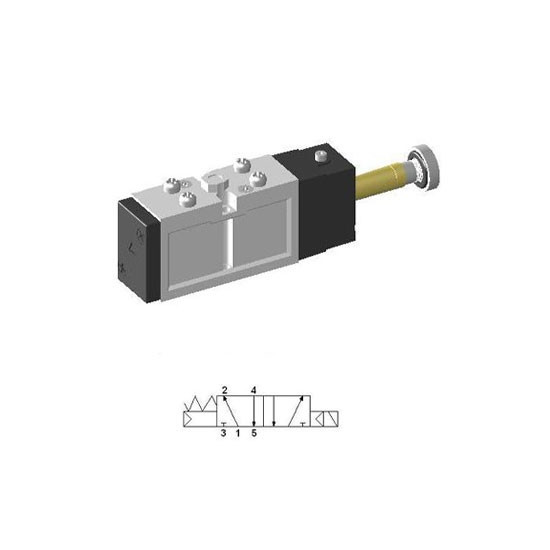

SIE Series Solenoid Valves for Valve Manifold Applications

SIE Series Solenoid Valves - Optimized Solution for Valve Manifold Mounting

The SIE series solenoid valves represent a specialized evolution within our range of solenoid valves, specifically designed for direct mounting on valve manifolds. This distinctive feature makes them ideal components for complex pneumatic systems where modularity, space savings, and ease of maintenance are fundamental requirements.

Distinctive Technical Features

- Specific design: Base adapted for direct mounting on valve manifolds without additional adapters

- Mounting pattern: Standardized configuration to ensure compatibility with various manifolds

- Available functions: 3/2, 5/2, and 5/3 way with different center positions

- Actuation types: Monostable (spring return) and bistable (double solenoid)

- Coil voltages: Available in 12V DC, 24V DC, 24V AC, 110V AC, and 230V AC

- Optimized sealing: Special seals to ensure tightness at the valve-manifold interface

- Visual indication: Integrated LED for operational status confirmation

- Manual override: Optional manual override for testing and maintenance

Advantages of the Modular Manifold System

The main difference between SIE solenoid valves and other conventional series lies in their optimized integration into manifold-based modular systems. This design offers significant advantages:

- Simplified pneumatic connections: Elimination of external tubing between valves, reducing potential leak points

- Centralized distribution: Air supply and exhaust through internal channels in the manifold

- Simplified maintenance: Ability to replace individual valves without disconnecting the entire system

- Installation density: More control functions in a smaller space

- Reduced installation time: Up to 70% less time compared to conventional individual valve systems

- Increased reliability: Fewer external pneumatic connections mean fewer potential failure points

Compatibility with Valve Manifolds

Our SIE solenoid valves are fully compatible with the range of modular manifolds we offer, allowing customized system configurations according to the specific needs of each application:

- Individual valve manifolds: For mounting a single valve with optimized connections

- Multi-port manifolds: For connecting 2, 4, 6, 8, or more valves in a single block

- Manifolds with multi-pin electrical interface: With a single connector for all control signals

- Manifolds with fieldbus communication: For direct integration with industrial control systems

- Manifolds with integrated pressure regulation options: For individualized control per station

Typical Applications

The SIE series with its manifold mounting configuration finds application in numerous industrial sectors, especially in:

- Packaging machinery with multiple synchronized actuators

- Automated production lines with reduced space requirements

- Robotic systems with demand for fast and reliable response

- Handling equipment with centralized control requirements

- Testing and validation systems with frequent reconfigurations

- Textile machinery with multiple pneumatic functions

- High-density pneumatic cylinder systems in limited spaces

The choice between a conventional solenoid valve and an SIE series valve for manifold mounting will primarily depend on the complexity of the system, the number of functions to control, and maintenance requirements. For applications with multiple control points concentrated in a limited space, the SIE series in combination with our valve manifolds offers the most efficient, compact, and reliable solution available in the market.

At Pneumatig.eu, we can advise you on the optimal configuration of your system, combining SIE solenoid valves and valve manifolds according to your specific needs, thus ensuring optimal performance with maximum reliability and ease of maintenance.

Login and Registration Form